The APROL ParameterCenter is a powerful solution for central management of system parameters in advanced automation projects. It enables the convenient storage, editing and organization of parameter sets from different runtime systems in the same CAE project. This significantly simplifies the entire parameterization process for system operators and service and commissioning teams.

When creating the equipment in the project, the desired system unit is first created and named. Specific equipment parameters are then assigned to it, which define the operating mode and properties of the unit. These include physical variables (e.g. fill level, temperature limits), process limit values and operating modes.

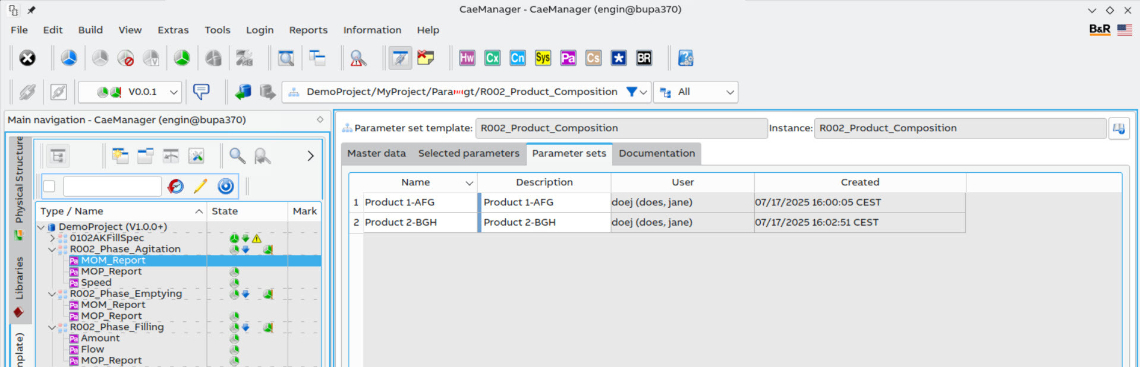

The desired equipment parameters for the respective system unit are selected in the parameter set template. This template is used to systematically define and manage all relevant parameters. Parameter set templates can be used to configure equipment objects in an efficient and standardized way.

The parameter set is used to define a product or to form a self-contained parameter set that can be used independently of a specific product. It is created or edited by the user in the ParameterCenter and specifies all the settings and target values required for targeted configuration of a production process or system unit. After editing, the parameter set can be loaded directly onto the system. The parameter set enables efficient product changes and process adaptations and ensures transparency and traceability of the respective settings.

Centralized functions

Intuitive navigation:

All runtime systems in a project can be selected directly via a selection dialog box. This allows quick and targeted access to project-specific parameter sets.

Versatile parameter handling:

Parameter sets can be edited, created or deleted on a project-specific basis. It is possible to transfer parameter sets between different runtime systems.

Efficient maintenance of parameters:

The maintenance of extensive parameter set templates is supported by a clear and structured list function. Filter and search options allow you to quickly identify relevant parameters or equipment.

Secure download/upload:

Parameter download and upload can be triggered specifically from both the engineering environment and the operator station. Transparent monitoring is provided via the current connection and transmission status.

Multi-user and rights management:

Access and editing of parameter data are securely controlled via the APROL user management system. This enables role-based teamwork, including the separation of engineering and operational functions.

Advantages for users

Increased flexibility:

Quick adaptation and reuse of parameter configurations for different systems and scenarios.

Optimized operational safety:

Central control prevents incorrect parameterization and supports documentation requirements through integrated version and change tracking.

Seamless integration:

The ParameterCenter is fully embedded in the APROL system landscape and works closely with other modules such as CAE Engineering and the DisplayCenter.

Cross-project overview:

System parameters are always displayed in the context of the associated runtime systems and equipment, so that even complex multi-runtime environments can be clearly managed.