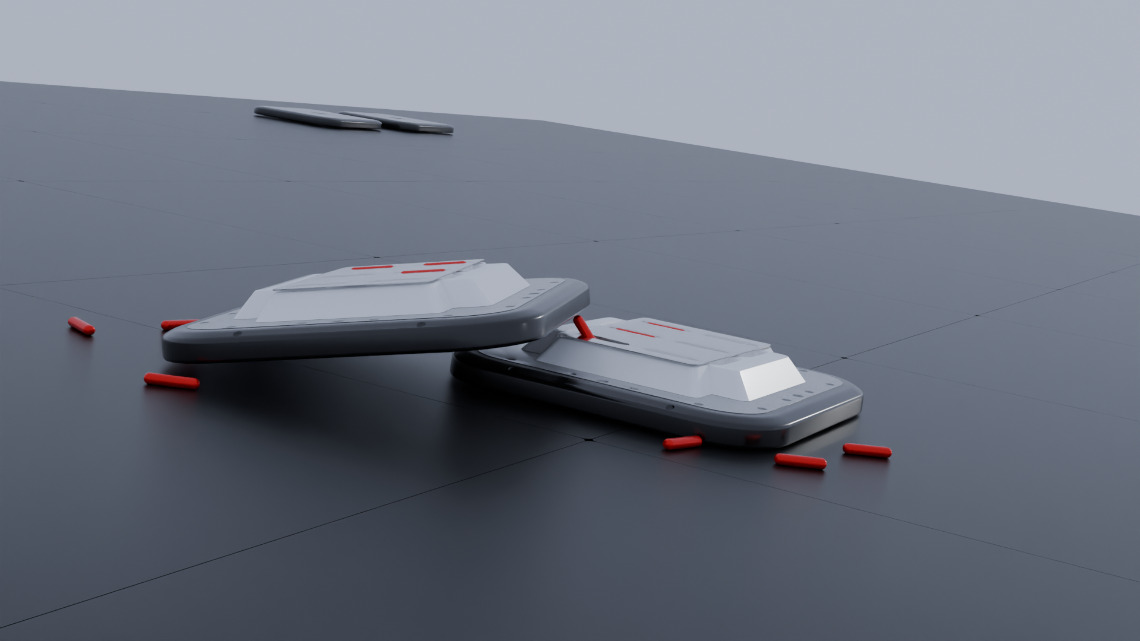

This course series is designed to guide you through understanding the concepts and features of ACOPOS 6D. You will comission your ACOPOS 6D controller, design and optimize layouts, use LaunchPad and Traffic Manager, and perform basic diagnostics on your ACOPOS 6D system. A blister packaging machine will guide you through all of the courses, providing a realistic use case for your hands-on experience.

Module 1 | ACOPOS 6D - Getting Started * * Course is free of carge, see details in the list below |

|---|---|

Module 2 | ACOPOS 6D - Basics |

Module 3 | ACOPOS 6D - Implementing process stations |

Module 4 | ACOPOS 6D - Additional functions and debugging |

Further information is provided below.

Module 1:

ACOPOS 6D - Getting Started

ACOPOS 6D - Getting Started

This online course is free of charge: English

Description | This course willguide you through collecting all required hard- and software components to get started with programming your ACOPOS 6D system. Besides you will get to know all physical components of an ACOPOS 6D system. Content:

|

|---|---|

Target group | Application engineers who want to work with ACOPOS 6D. |

Requirements |

|

Topic duration | About 1 hour |

Hardware used | The online course is based on following hardware:

Simulation? |

Software used |

|

Module 2:

ACOPOS 6D - Basics

ACOPOS 6D - Basics

Description | This course will guide you through understanding the concepts and features of ACOPOS 6D. Learn how to design layouts, use LaunchPad and Traffic Manager, and perform basic shuttle movements in the lessons provided to you in this course. Content:

|

|---|---|

Target group | Application engineers who want to work with mapp 6D. |

Requirements |

|

Topic duration | About 6 hours |

Hardware used | The online course is based on following hardware:

|

Software used |

|

Module 3:

ACOPOS 6D - Implementing process stations

ACOPOS 6D - Implementing process stations

Description | This course will guide you in using different function blocks of McAcp6D library to implement various shuttle movement sequences at the different process stations of a blister packaging machine. Content:

|

|---|---|

Target group | Application engineers who want to work with mapp 6D. |

Requirements |

|

Topic duration | About 4 hours |

Hardware used | The online course is based on following hardware:

Simulation? |

Software used |

|

Module 4:

ACOPOS 6D - Additional functions and Debugging

ACOPOS 6D - Additional functions and Debugging

Description | This course will show you some additional functions of the ACOPOS 6D system for advanced shuttle handling and ways to monitor and debug your system with different tools.. Content:

|

|---|---|

Target group | Application engineers who want to work with mapp 6D. |

Requirements |

|

Topic duration | About 2 hours |

Hardware used | The online course is based on following hardware:

Simulation? |

Software used |

|